Impartance of Shoes

Impartence of Shoes

Footwear and foot protection can be found found in the beginning of the 20th century, when industrial safety gear first became an issue. Previously it was a cheaper to replace an injured worker than to introduce safety measure.

The first protective boots were wooden boots, called as sabots. A sabot can be defined as a kind of simple shoes, shaped and hollowed out from a single block of wood, traditionally worn by French and Breton peasants. These protected workers from falling objects. Sabots protected farmers in the field from sharp objects and protected toes in case of a horse or cow stepped on them. During the early industrial revolution, workers were used sabots to destroy machinery by throwing them into the gears of factories to stop production. The word sabotage came on this activity.

These boots were invented at the end of World War II in the Germany. These were originally mean for workers to help protect them as they worked. Before these boots was invented, workers used to wear leather boots or wooden clogs. Currently, however, several other users including civilians and military personnel use these boots.

Weather protection

Colder climates can lead to injuries such as frost bite and hypothermia, and those dangers shouldn’t be overlooked in the workplace. People who work outside in the winter are at risk, as well as employees who work in wet or refrigerated environments.

Furthermore, the cold can exacerbate some lesser known workplace injuries. For example, Raynaud’s Syndrome is a disease where the fingers can turn white from poor blood flow. This condition, related to vibration from power tool use, is made worse when employees are exposed to cold temperatures. In some cases, this disorder can impact the feet, too, so keeping the feet warm and comfortable in conjunction with other measures for keeping the body warm is important.

Not all footwear is waterproof or insulated to provide protection against the cold, rain and snow, so be sure to select shoe options that are made from appropriate materials.

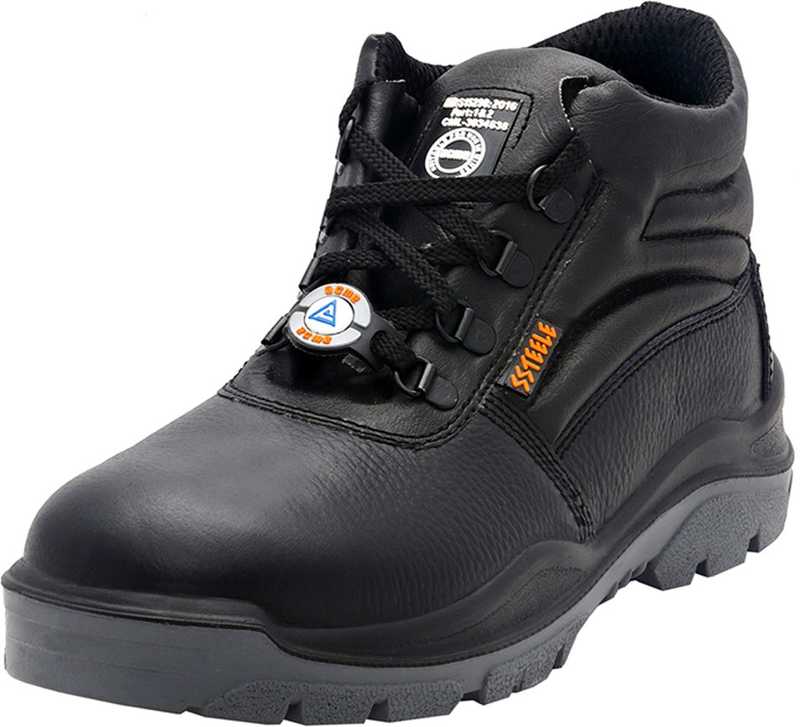

Here are some key factors to consider when choosing a shoe:

Steel toes to protect against falling objects, which cause 60% of all foot injuries. Where there are electrical hazards, a fibreglass toe should replace the typical steel toe.

Good traction to protect against slips and falls, which the Bureau of Labor Statistics said were responsible for about 329,000 lost workdays in 1994. Depending on the environment, consider cleats, or a shoe with an abrasive, gritted, grooved, spiked or studded sole.

Proper chemical protection. Boots and shoes made of rubber, PVC or neoprene (depending on the chemical) are needed.

Employee comfort. If a shoe is unwieldy or heavy, chances are it will not be worn. Give workers a choice of footwear colours and styles but only after you are satisfied that all of those to be considered provide adequate protection.

Footwear and foot protection can be found found in the beginning of the 20th century, when industrial safety gear first became an issue. Previously it was a cheaper to replace an injured worker than to introduce safety measure.

The first protective boots were wooden boots, called as sabots. A sabot can be defined as a kind of simple shoes, shaped and hollowed out from a single block of wood, traditionally worn by French and Breton peasants. These protected workers from falling objects. Sabots protected farmers in the field from sharp objects and protected toes in case of a horse or cow stepped on them. During the early industrial revolution, workers were used sabots to destroy machinery by throwing them into the gears of factories to stop production. The word sabotage came on this activity.

These boots were invented at the end of World War II in the Germany. These were originally mean for workers to help protect them as they worked. Before these boots was invented, workers used to wear leather boots or wooden clogs. Currently, however, several other users including civilians and military personnel use these boots.

Weather protection

Colder climates can lead to injuries such as frost bite and hypothermia, and those dangers shouldn’t be overlooked in the workplace. People who work outside in the winter are at risk, as well as employees who work in wet or refrigerated environments.

Furthermore, the cold can exacerbate some lesser known workplace injuries. For example, Raynaud’s Syndrome is a disease where the fingers can turn white from poor blood flow. This condition, related to vibration from power tool use, is made worse when employees are exposed to cold temperatures. In some cases, this disorder can impact the feet, too, so keeping the feet warm and comfortable in conjunction with other measures for keeping the body warm is important.

Not all footwear is waterproof or insulated to provide protection against the cold, rain and snow, so be sure to select shoe options that are made from appropriate materials.

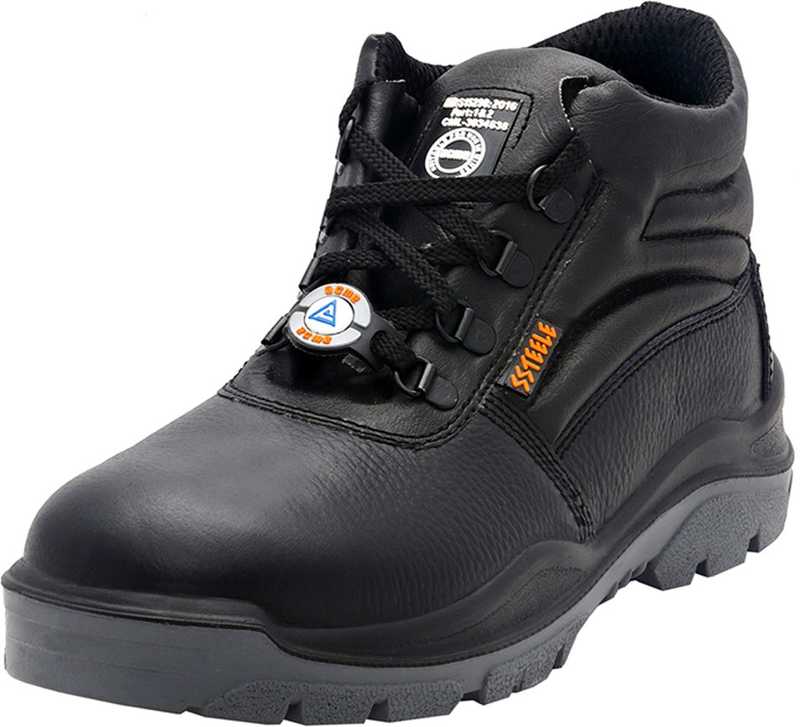

Here are some key factors to consider when choosing a shoe:

Steel toes to protect against falling objects, which cause 60% of all foot injuries. Where there are electrical hazards, a fibreglass toe should replace the typical steel toe.

Good traction to protect against slips and falls, which the Bureau of Labor Statistics said were responsible for about 329,000 lost workdays in 1994. Depending on the environment, consider cleats, or a shoe with an abrasive, gritted, grooved, spiked or studded sole.

Proper chemical protection. Boots and shoes made of rubber, PVC or neoprene (depending on the chemical) are needed.

Employee comfort. If a shoe is unwieldy or heavy, chances are it will not be worn. Give workers a choice of footwear colours and styles but only after you are satisfied that all of those to be considered provide adequate protection.

Comments

Post a Comment